TRUSSES

ROOF TRUSSES

We ensure precision; our roof trusses are custom manufactured to a perfect fit for your project. Our roof trusses are engineered with framer-friendly layouts to provide a solution to any architecturally drawn design. This process and our experience allows us to engineer the most affordable and time-saving roof trusses on the market. You can be certain that you will get the strength and durability from an S.R. Sloan truss because they are built for optimal structural integrity.

ROOF TRUSSES

We ensure precision; our roof trusses are custom manufactured to a perfect fit for your project. Our roof trusses are engineered with framer-friendly layouts to provide a solution to any architecturally drawn design. This process and our experience allows us to engineer the most affordable and time-saving roof trusses on the market. You can be certain that you will get the strength and durability from an S.R. Sloan truss because they are built for optimal structural integrity.

Contact Us To Get Started.

WHY USE S.R. SLOAN ROOF TRUSSES?

By using S.R. Sloan roof trusses, you will see total project cost savings because…

Roof Trusses Save You Money

Pre-built roof trusses dramatically cut labor costs at the job site by cutting the time needed to roof by eliminating the guesswork.

Roof Trusses Are Versatile

Roof trusses provide more design flexibility than conventional framing. They can stretch much longer spans and offer numerous custom design options.

Our Roof Trusses Are Top Quality

Our roof trusses are built in a controlled environment by experienced assemblers ensuring your trusses will stand the test of time.

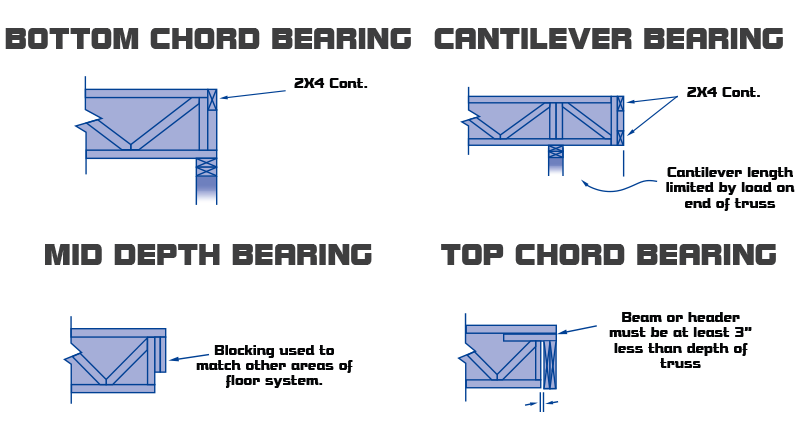

FLOOR TRUSSES

Our floor trusses are of the highest quality, built for flexibility in design, in a quality controlled environment. You can expect every truss to arrive pre-engineered, customized to the exact specifications of your project. We can provide a trimmable end truss to allow up to 12” on each end to be trimmed in case the foundation you are working with isn’t perfect. The open webbed construction of a floor truss allows for utilities like wire, conduit, pipes, and ducts to be run through them with ease, cutting down on job site waste and an increase in the stability of the floor. Also, they provide the ability to span a longer length, which means your project will use fewer beams, columns, footings, and bearing walls, allowing for open concept designs for space below – perfect for a finished basement in a residential application. In commercial applications, floor trusses are strong enough to handle the 100-pound minimum live loads that are often called for and are the most economical choice.

FLOOR TRUSSES

Our floor trusses are of the highest quality, built for flexibility in design, in a quality controlled environment. You can expect every truss to arrive pre-engineered, customized to the exact specifications of your project. We can provide a trimmable end truss to allow up to 12” on each end to be trimmed in case the foundation you are working with isn’t perfect. The open webbed construction of a floor truss allows for utilities like wire, conduit, pipes, and ducts to be run through them with ease, cutting down on job site waste and an increase in the stability of the floor. Also, they provide the ability to span a longer length, which means your project will use fewer beams, columns, footings, and bearing walls, allowing for open concept designs for space below – perfect for a finished basement in a residential application. In commercial applications, floor trusses are strong enough to handle the 100-pound minimum live loads that are often called for and are the most economical choice.

Contact Us To Get Started.

WHY USE S.R. SLOAN FLOOR TRUSSES?

By using S.R. Sloan floor trusses, you will see total project cost savings because…

Cost-Efficient Design Savings For a Better Quality Floor

At S.R. Sloan, we customize each floor truss to meet the needs of your job. We take into consideration the required stiffness, depth, and span. Using the latest technology, we design your floor trusses for optimal performance, cost, and installation efficiency all while minimizing waste. In commercial applications, our floor trusses are, by far, the most economical choice due to the load capacities we can construct for use.

Time & Labor Cost Savings

Floor trusses are designed for quick installation, which in turn saves you money that would be spent on labor costs for your project. No manpower is needed to prep during the construction process for trade work, including plumbing, ventilation ducts, and conduits.

Strength & Flexibility

Our floor trusses are perfect for open-design floor plans. They give you the ability to run longer spans, reducing the need for bearing walls, beams, or columns which in turn saves on time and construction costs. Floor trusses allow you to create a more solid floor, minimizing the amount of shrinkage, warping, or twisting, successfully reducing the potential of callbacks to the job site for an unsatisfactory job.

FAQ’S

What types of trusses are available?

S.R. Sloan builds roof and floor trusses in an infinite number of designs, shapes, and sizes. Sketch a truss or building, and we can supply you with a truss design to fit your needs.

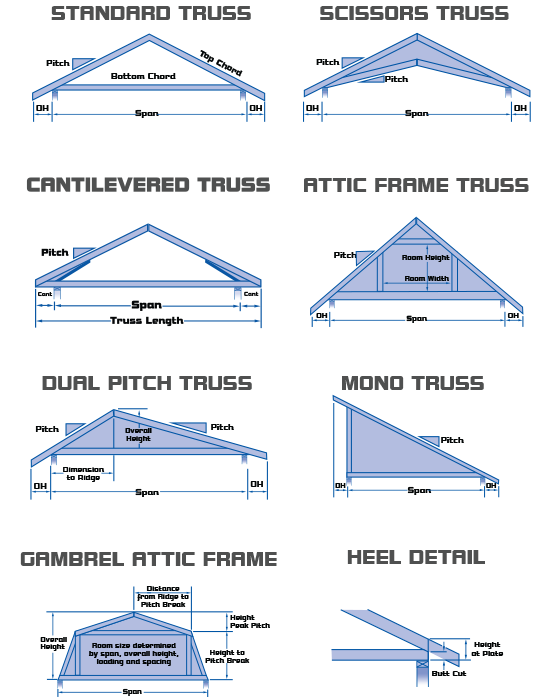

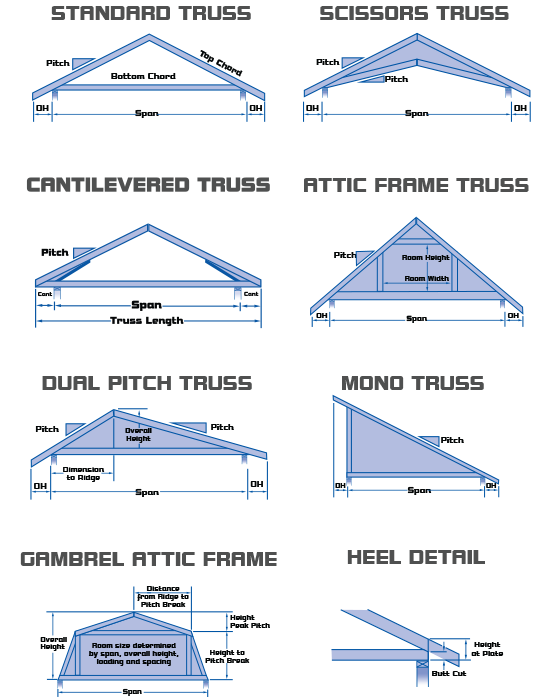

What types of roof truss profiles are offered?

We offer every design of wood trusses at S.R. Sloan. We can build anything from a simple common truss to more complex designs such as a scissor truss, gambrel truss, attic truss, cantilevered truss, and even a dual pitch truss. We have also constructed many custom-style trusses. Whatever your design plans call for, our design team will work diligently to fulfill your needs.

Do you offer design assistance for preliminary quotes?

We do offer assistance on preliminary quotes. Feel free to give our design team a call if you have a question or to set up an appointment for a design consultation.

Can I get engineered sealed designs/drawings for my project?

Yes, after we quote you the job. All you have to do is place the order with an authorized dealer and we can provide sealed truss drawings for your project upon request.

Do you supply truss hangers and clips with the order?

Yes, we typically provide truss to truss connections on request. We can provide addition hangers and uplift connections.

Who do I contact for more information?

Feel free to contact any member of our sales team. Whether you speak to an outside or inside sales representative, they will be able to answer your question or direct you to the correct person at S.R. Sloan to speak to.

Are fire rated and pressure treated trusses available?

Yes, fire rated trusses are available at S.R. Sloan. Please allow for additional manufacturing time in your construction process. Your sales representative will be able to give you an estimated time of delivery.

Who do I hire to install the trusses I order?

Any qualified contractor will be able to install the trusses we provide. If you are unsure of whom to hire, we may be able to recommend a contractor you can contact for pricing.

How are the trusses installed to the bearing walls or beams?

Please follow the BCSI-B1 summary sheet recommendations that we provide with every delivery. Also, please consult the engineered truss drawings which are also provided on delivery. On a large job, the engineer or architect of record should also be consulted.

For more information: BCSI-B1 summary sheet

Can trusses be modified at the job site?

No, not without consulting S.R. Sloan first. Often, minor modifications can be done but must be verified by our engineers before being made in the field.

**Do not cut, modify, or drill through a truss without first consulting S.R. Sloan, Inc.**

How do I attach a piggyback truss to the base truss?

We will send you a detailed guide with your sealed truss drawings or you can always refer to the information found on the www.alpeng.com website.

In the notes, on the top of your shop drawings, it says to reference sheet A10030020109, GBLLETIN0212, GABRST020109, etc., where do I find this information?

Please refer to the Knowledge tab in the menu of our website and/or the www.alpeng.com website for more information.

Can I get my order sooner than the current scheduled delivery date?

Quite often, yes. First, we will need to know when you actually need your order; then your order will need to be completely approved. After we receive all of the necessary information and paperwork, we will do what we can to expedite your order.

What are your current production lead times?

Please refer to the scrolling banner at the bottom of this page for the most current lead times. For a more exact answer, just give us a call! We will need to know what exactly you are planning to build, where it is going, and when you would need it. We also need to know if this is an order already, and if so, if it is approved or being approved shortly.

What is the approval process?

We require all orders to be reviewed and approved by the end user in writing. Often, this is a simple process of verifying quantity, length, pitch, overhang, and loading. On more complicated projects, a complete review of individual designs and placement is required by all interested parties ie. Architect, engineer, contractor. This process is simply to ensure that the proper product is provided and to prevent mistakes from happening.

Lead times may vary for different locations

NEW YORK

8111 Halsey Rd Whitesboro, NY 13492

800-366-7562

315-736-7740

PENNSYLVANIA

87 Pinedale Industrial Rd Orwigsburg, PA 17961

570-366-8934

570-366-0807

BALLSTON SPA- OFFICE ONLY

61 Rowland St. Suite 201 Ballston Spa, NY 12020

CONTACT US